x

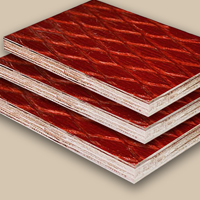

Chequered Plywood

Product Details:

- Formaldehyde Emission Standards E1 Standard

- Glue Type PF resin

- Grade BWP (Boiling Water Proof)

- Tolerance 0.5 mm

- Feature Anti-slip, high strength, weather resistance

- Core Material Gurjan or hardwood

- Thermal Conductivity Low

- Click to View more

X

Chequered Plywood Price And Quantity

- 500 , , Piece

Chequered Plywood Product Specifications

- 0.5 mm

- BWP (Boiling Water Proof)

- 12 mm to 25 mm

- PF resin

- E1 Standard

- Low

- Chequered Plywood

- Gurjan or hardwood

- Anti-slip, high strength, weather resistance

- Phenol Formaldehyde (PF)

- Less than 8%

- 800 Gram per cubic centimeter(g/cm3)

- Smooth hardwood veneer

- Hardwood, Gurjan timber

- Chequered anti-slip pattern

- High load-bearing capacity

- Textured, anti-skid chequered design

- <10%

- 2440 1220 mm / 8 4 ft

Chequered Plywood Trade Information

- 5000 , , Piece Per Day

- 1 Week

Product Description

Chequered Plywood

The offered Chequered Plywood is made available by us for use in the various industrial applications. The offered plywood is one of the best transportation purpose plywood. The ply has a chequered pattern on its surface. Because of high pressure, the panel develops high density that can sustain high traffic on flooring in public & industrial use. The offered Plywood is excellent for outdoor use, for framing walls or building floors, for crafting kitchen or bathroom cabinets, and for projects that require a curve. The offered Chequered Plywood is very effective and safe for use. It is easy to use.

Engineered for Heavy-Duty Performance

Chequered Plywood is manufactured using Gurjan or high-quality hardwood, pressed under high temperature and pressure. The result is a durable panel with high impact resistance, excellent screw holding, and a load capacity suited for challenging environments like transport vehicles and industrial settings. Its anti-slip chequered design ensures safety where traction is essential.

Moisture Protection and Environmental Safety

The edges of each board are sealed to prevent moisture ingress, significantly extending lifespan in damp environments. Chequered Plywood uses E1 grade low formaldehyde glue for healthier indoor air quality, complying with strict global environmental standards. Its low water absorption makes it reliable for long-term use in areas exposed to occasional water splashes.

FAQs of Chequered Plywood:

Q: How does the chequered design benefit flooring applications in transport and industrial settings?

A: The chequered anti-slip pattern provides superior grip, reducing the risk of slips and falls in trucks, buses, walkways, and industrial shelves. This design ensures safety for users, even in wet or oily conditions.Q: What makes Chequered Plywood suitable for high-load and heavy-duty applications?

A: Manufactured from robust Gurjan or hardwood material and bonded with BWP phenol formaldehyde glue, this plywood offers excellent screw holding, high impact resistance, and a dense core (800 g/cm), making it capable of supporting heavy loads and frequent use.Q: When should I choose laminated versus non-laminated Chequered Plywood?

A: Laminated options offer additional surface protection and can enhance aesthetics or durability, making them suitable for environments with higher wear or where ease of cleaning is required. Non-laminated types are ideal where budget or specific utility is a priority.Q: Where can Chequered Plywood be used most effectively?

A: It is ideal for floors of transportation vehicles such as trucks and buses, industrial shelves, and walkways. The boards high strength, anti-slip design, and weather resistance make it suitable for intense, high-traffic usage areas.Q: What process ensures the plywoods resistance to moisture and environmental safety?

A: The panels are hot-pressed using phenol formaldehyde resin and sealed on all edges, resulting in superior moisture protection. Compliance with E1 formaldehyde emission standards ensures minimal impact on indoor air quality.Q: How is the plywoods durability and edge protection maintained over time?

A: Edges are meticulously sealed to block moisture, and the chequered surface is manufactured for long-lasting anti-slip performance. The smooth hardwood back also helps prevent warping and wear, ensuring durability in various conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Chequered Plywood' category

|

AVIAN ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free